Backflow Testing Brisbane

Licensed plumber with proper training, fully insured, and offers clear set prices so there are no surprises.

What Is Backflow?

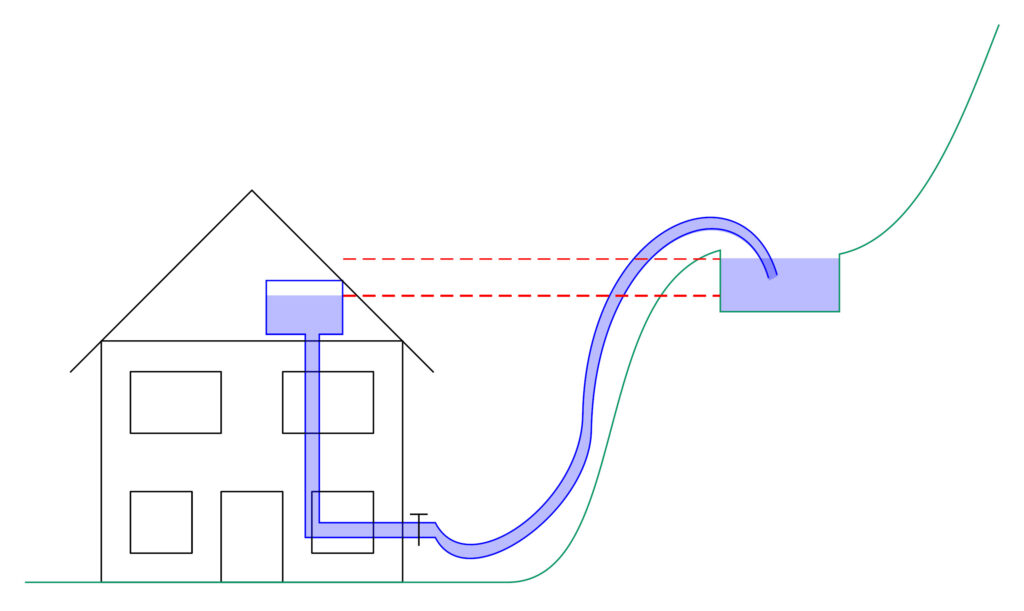

Backflow happens when water flows the wrong way in your pipes.

This can happen if there’s a big drop in water pressure, like when a water main breaks or during a fire when lots of water is being used. That’s called back siphonage.

It can also happen if something like a water pump pushes water into your pipes harder than the water from the street. That’s called back pressure.

If dirty water (like from a garden hose left in a bucket) gets connected to your clean water pipes, and the pressure changes, that dirty water can get sucked into your drinking water, which can make it unsafe.

What Is A Backflow Prevention Device?

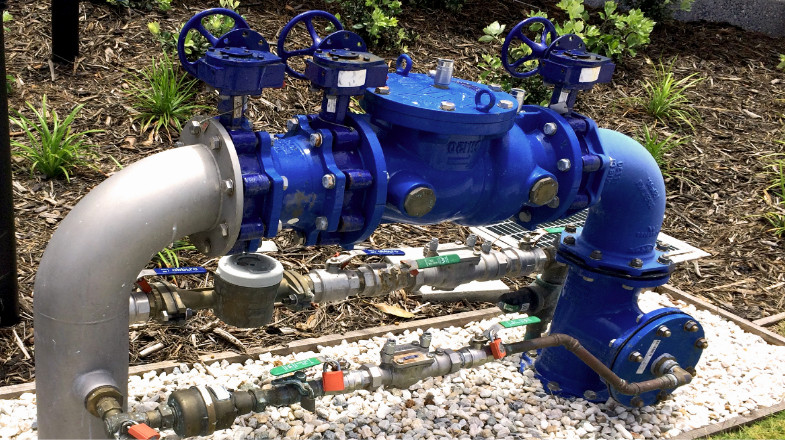

A backflow prevention device is used to protect clean drinking water from contamination caused by backflow.

In plumbing systems, water is normally kept at high pressure to flow properly through taps, showers, and other fixtures. This device ensures that water only flows in one direction, preventing any polluted water from entering the clean supply.

Types Of Backflow Prevention Devices

Backflow prevention devices are essential for protecting drinking water from contamination caused by reverse water flow. Here are the main types commonly used in residential, commercial, and industrial settings:

- Air Gap: An air gap is a non-mechanical solution that creates a physical space between the water outlet and the highest potential water level in a fixture or container. Commonly found in sinks and bathtubs, it effectively prevents back-siphonage in situations where mechanical devices are not practical.

- Atmospheric Vacuum Breaker (AVB): A simple, non-mechanical device that prevents back-siphonage by allowing air into the system when water pressure drops. AVBs are typically used in low-risk applications such as garden irrigation systems.

- Pressure Vacuum Breaker (PVB): A mechanical device that includes a check valve and air inlet valve to prevent back-siphonage. Commonly installed in irrigation systems, PVBs provide a higher level of protection than AVBs and must be mounted at least 30cm above the highest downstream outlet.

- Double Check Valve Assembly (DCVA): This device features two check valves arranged in series and is designed to prevent both back-siphonage and backpressure. DCVAs are suitable for low to medium hazard situations, such as in residential and commercial plumbing systems.

- Reduced Pressure Zone Device (RPZ): Offering the highest level of protection, RPZs include two independent check valves and a pressure relief valve. These devices are used in high-risk environments like commercial kitchens, hospitals, and industrial facilities where contamination risks are significant.

Do You Need A Backflow Prevention Device?

Some places need backflow prevention devices because they could make the main water supply dirty if something goes wrong. These places include:

- Air conditioning towers

- Restaurants

- Swimming pools

- Funeral homes

- Car wash businesses

- Laundromats and dry cleaners

- Shops

- Factories and places that make chemicals

- Boilers and steam pipes

- Hotels

- Irrigation systems (for watering gardens or crops)

- Fire hose reels or hydrants

- Underground rainwater tanks

What Is A TMV?

A Thermostatic Mixing Valve (TMV) is a plumbing device designed to regulate water temperature at taps and showerheads. Its main function is to deliver water at a consistent, safe temperature, helping to prevent scalding and ensure user comfort.

To protect users from injury, especially in settings like homes, hospitals, and care facilities, TMVs are set to ensure water does not exceed 45°C.

About Crew Plumbing

At Crew Plumbing, we are committed to ensuring the safety and compliance of your backflow prevention systems, protecting the potable water supply of Brisbane.

We provide professional testing and maintenance of backflow prevention devices for residential, commercial, and industrial properties. Whether you require annual testing or ongoing support, our experienced team ensures your devices function correctly and meet all regulatory standards.

We pride ourselves on delivering reliable service and expert advice, ensuring your system remains compliant and fully operational within required timeframes.

Contact us today for a quote or to schedule your backflow prevention test, and enjoy the confidence of knowing your water supply is safe and protected.

What Our Clients Say

Show Up On Time

Price Up-Front

Get It Right First Time

Leave Your Place Clean

Do I Need To Do Backflow And/Or TMV Testing?

Your Backflow Device and TMV Valve should be checked at least once a year to make sure they’re working properly.

Only someone with the right license is allowed to test or inspect these devices. At Crew Plumbing, our team is fully trained and licensed to install and test Backflow Devices and TMVs. By law, if you have a testable backflow device, you must also register it with your local City Council.

Crew Plumbing offers a full service that includes checking, testing, and fixing these devices. TMVs also need new parts like the thermostat and o-rings every 5 years, plus a check-up at least once a year.

What Factors Determine The Need For Backflow Testing?

The need for backflow testing depends on a few things, like where your property is, what local rules apply, and the kind of backflow prevention device you have. Different areas in Brisbane may have their own rules, so it’s important for property owners to know what’s required.

The type of device you have also affects how often it needs to be tested. For example:

- RPZ (Reduced Pressure Zone) Device: This is used in places with a high risk of water getting dirty. Because it’s so important, it usually needs to be tested every year or as often as local rules say

- DCVA (Double Check Valve Assembly): This is used in lower-risk places. It may not need testing as often as an RPZ, but it still needs regular checks to make sure it’s working properly.

What Are Your Responsibilities:

If you own a backflow prevention device in Queensland, there are some important things you need to do to help keep the city’s drinking water safe.

1.

Register

Register your device with your local council. This is required by law (Plumbing and Drainage Act 2018).

2.

Test It

Get it tested every year by a licensed plumber, like our team at Crew Plumbing. Your council will send you reminders and a yearly fee notice so you don’t forget. You could be fined if your device isn’t tested or registered on time.

3.

Keep Records

Keep testing records. We can help with this, including sending the official test report (Form 9) to your local council. We’ll also remind you when your next test is due.

The council can fine you if you don’t follow these rules. Contact us to stay on track, avoid penalties, and help protect the community’s clean water supply.

Why Is Backflow Testing Important?

A backflow prevention device is a special valve that stops dirty or polluted water from getting into the clean drinking water supply.

Sometimes, if there’s a big drop in water pressure, like when a pipe bursts, a fire hydrant is used, or a pump is running, water can start to flow the wrong way. If your backflow device isn’t working, that dirty water could go back into the main water supply and make it unsafe to drink.

That’s why it’s super important to have your backflow device tested every year.

It doesn’t happen often, but when it does, it can be a big problem. So it’s something you shouldn’t skip!

I’m Not Sure When My TMV/Backflow Test Is Due

If you don’t remember the last time your TMV or Backflow device was tested, it’s a good idea to book a test now.

Crew Plumbing’s licensed team can come out and do the testing for you. We’ll also send you a reminder every 12 months, so you don’t forget to get it checked next time.

Can I Get The Backflow Device Removed So I Don’t Have To Do Testing Every Year?

Backflow prevention devices are put in when there’s a chance that dirty water could get into the clean water supply.

Talk to one of our plumbers, they can check if you still need the device. If there’s still a risk, the device has to stay and be working properly.

Looking for an expert backflow plumber in Brisbane?

Backflow testing might sound tricky, but we’re here to handle it for you. We’ll make sure everything is up to code, so you don’t have to worry about a thing.

Our Services In Brisbane

We offer lots of backflow testing services, including:

Installing backflow devices and valves

Yearly check-ups and writing a report

Sending the report to your local City Council for you

Testing and fixing all types of backflow valves from brands like Wilkins, Febco, Watts, Tyco, and more